Steel Fabrication Trends: Innovations in Cutting, Welding, and Forming Techniques

In the realm of steel fabrication, advancements in cutting-edge technology are revolutionizing the way steel structures are crafted. From precision cutting to seamless welding and intricate forming, the steel fabrication industry is experiencing a dynamic shift propelled by innovative techniques. These trends are not only enhancing the efficiency and quality of steel production but also contributing to the development of robust and sophisticated structures that define our modern world.

Cutting-Edge Precision:

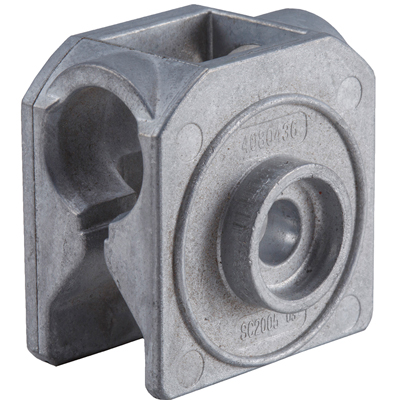

The incorporation of CNC machines has enhanced precision and accelerated production speed. By minimizing human error and material wastage, these machines have streamlined resource utilization, rendering steel fabrication more cost-efficient and environmentally friendly. Moreover, the capacity of CNC machines to handle diverse materials, such as stainless steel, aluminum, and carbon steel, has broadened the horizons in the domain of steel fabrication. This adaptability has empowered architects and engineers to realize designs that were previously deemed impractical or unachievable.

Seamless Welding Innovations:

The advancements in robotic welding have not only increased the efficiency of the welding process but have also improved the working conditions for welders. By automating the more repetitive and hazardous aspects of welding, such as working in confined spaces or under extreme temperatures, these systems have reduced the risk of workplace accidents and injuries. This has not only improved the overall safety standards within the industry but has also attracted a new generation of workers who are drawn to the technological sophistication and safety protocols associated with modern steel fabrication.

Moreover, the integration of augmented reality (AR) and virtual reality (VR) technologies in the training of welders has streamlined the learning process, allowing aspiring welders to gain practical experience in a simulated environment. This immersive training approach has accelerated the development of skilled labor within the industry, addressing the ongoing demand for qualified professionals and ensuring the continuity of the steel fabrication workforce.

Intricate Forming Techniques:

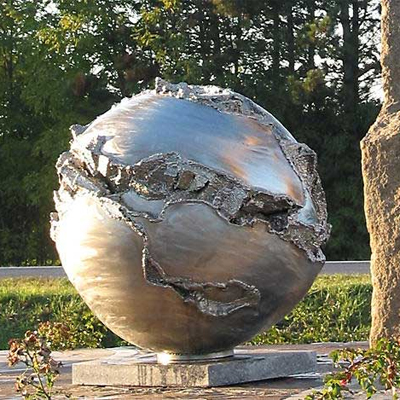

The use of CAD software alongside advanced shaping techniques has simplified the creation of intricate designs and complex geometries. This has not only broadened the creative potential in architectural design but has also equipped engineers with the means to construct structures that prioritize strength, durability, and functionality. The capability to simulate and assess the performance of steel components under different circumstances has empowered engineers to design structures capable of enduring environmental adversities, such as seismic disturbances and harsh weather conditions, thus ensuring the durability and longevity of the constructed landscape.

The Future of Steel Fabrication:

With the industry's ongoing adoption of digitalization and automation, the incorporation of Internet of Things (IoT) devices and sensors is anticipated to offer immediate visibility into the fabrication process. This will enable manufacturers to monitor production parameters and swiftly identify any irregularities. This proactive stance towards quality control and maintenance is poised to further augment the efficiency and dependability of steel fabrication, solidifying the industry's standing in delivering durable and top-notch structures.

Moreover, the study of sustainable materials and fabrication methodologies, such as the adoption of advanced coatings and corrosion-resistant alloys, is expected to prolong the lifespan and environmental viability of steel structures. By placing emphasis on the advancement of eco-friendly materials and procedures, the industry is aligning itself with worldwide endeavors to mitigate the environmental consequences of construction activities, thus contributing to the establishment of a more sustainable and robust built environment for generations to come.

In conclusion, the continued evolution of cutting, welding, and forming techniques in the steel fabrication industry represents a paradigm shift in the way we conceive, design, and construct the built environment. These advancements not only underscore the industry's commitment to innovation and excellence but also highlight its pivotal role in shaping a sustainable and resilient future. As steel fabrication continues to embrace technological progress and sustainable practices, it remains a cornerstone of modern infrastructure development, contributing to the realization of resilient and visually striking structures that define the landscapes of tomorrow.