The Evolution of High-Strength Steel: Applications and Advantages for B2B Industries

Introduction

High-strength steel has emerged as a game-changer in various industries, revolutionizing the way manufacturers design and produce products. This evolution in steel technology has significantly impacted B2B industries, offering a wide range of applications and advantages. In this article, we will delve into the evolution of high-strength steel, exploring its applications and the considerable benefits it brings to businesses.

Understanding High-Strength Steel

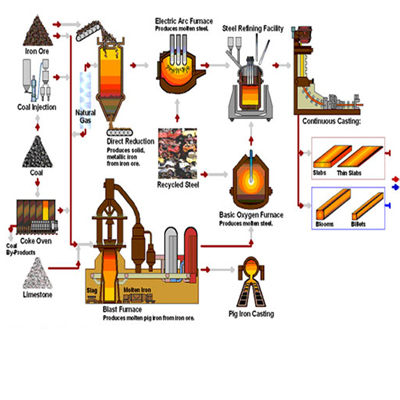

High-strength steel is a type of steel that exhibits enhanced strength properties compared to traditional steel. This improvement is achieved through various alloying elements and heat treatment processes, resulting in a material that can withstand higher stress, pressure, and impact. The evolution of high-strength steel involves advancements in metallurgy, manufacturing processes, and the development of new alloys to meet specific industry requirements.

Applications in B2B Industries

a. Automotive Sector

One of the primary beneficiaries of high-strength steel is the automotive industry. Manufacturers use this advanced material to build lighter and stronger vehicle structures, improving fuel efficiency, safety, and overall performance. High-strength steel components can be found in critical areas such as chassis, frames, and safety features, contributing to the development of more robust and lightweight vehicles.

b. Construction and Infrastructure

High-strength steel plays a crucial role in the construction and infrastructure sector, contributing to the development of robust and resilient structures. Engineers and builders widely apply this material in various contexts, such as constructing bridges, high-rise buildings, and other infrastructure projects. By incorporating high-strength steel, it becomes possible to fabricate structures that are not only lighter but also maintain high levels of strength and safety. This, in turn, results in projects that are more sustainable and cost-effective.

c. Aerospace Industry

In the aerospace industry, where weight holds paramount importance, high-strength steel is utilized in the production of various aircraft components. Ranging from the fuselage to landing gear, the aerospace sector takes advantage of the remarkable strength-to-weight ratio provided by high-strength steel. This material proves instrumental in decreasing the overall weight of aircraft, thereby improving fuel efficiency and performance, all the while ensuring the structural integrity is maintained.

d. Energy Sector

In the energy sector, particularly in the production and transportation of oil and gas, high-strength steel is indispensable. Pipelines, drilling equipment, and storage tanks are often subjected to harsh conditions, requiring materials that can withstand extreme pressures and environmental factors. High-strength steel ensures the reliability and durability of equipment in this demanding industry.

Advantages for B2B Industries

a. Weight Reduction and Fuel Efficiency

One of the significant advantages of high-strength steel in B2B industries is its ability to contribute to weight reduction. In sectors such as automotive and aerospace, lighter materials translate to improved fuel efficiency. This is crucial for businesses looking to meet stringent environmental regulations and reduce operational costs associated with fuel consumption.

b. Enhanced Safety and Durability

The superior strength properties of high-strength steel enhance the safety and durability of products across various industries. In automotive manufacturing, for example, the use of high-strength steel in key structural components improves crashworthiness and overall vehicle safety. Similarly, in construction and infrastructure, structures built with high-strength steel exhibit increased resilience against natural disasters and wear over time.

c. Cost Efficiency

While high-strength steel may have a higher initial cost compared to traditional steel, its advantages in terms of weight reduction, durability, and performance often result in long-term cost savings. Businesses can benefit from reduced maintenance costs, improved energy efficiency, and extended product lifespan, ultimately leading to a positive impact on the bottom line.

d. Environmental Sustainability

The use of high-strength steel aligns with the growing emphasis on environmental sustainability in B2B industries. By enabling weight reduction and improving fuel efficiency, high-strength steel contributes to the reduction of greenhouse gas emissions. Additionally, the longer lifespan of products manufactured with high-strength steel reduces the need for frequent replacements, further minimizing environmental impact.

Challenges and Future Developments

Despite its numerous advantages, the widespread adoption of high-strength steel in B2B industries faces challenges such as processing difficulties, cost concerns, and the need for specialized equipment. However, ongoing research and development efforts are focused on addressing these challenges. Future developments may include the introduction of even more advanced alloys, improved manufacturing processes, and increased collaboration between material scientists and industries to optimize the use of high-strength steel.

Conclusion

The evolution of high-strength steel has had a profound impact on B2B industries, offering a versatile and reliable material that enhances product performance across various applications. From automotive manufacturing to aerospace and construction, the advantages of high-strength steel, including weight reduction, enhanced safety, cost efficiency, and environmental sustainability, make it a preferred choice for forward-thinking businesses. As technology continues to advance, we can expect further innovations in high-strength steel, solidifying its place as a cornerstone in the materials used by B2B industries worldwide.