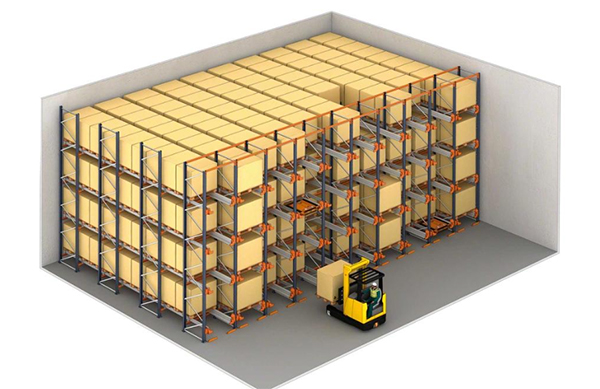

Automated Pallet Storage

The Pallet Shuttle is a high-density storage system where a shuttle, powered by an electric motor, runs along rails inside a storage channel. By replacing forklifts, this radio shuttle solution considerably reduces operating times and enables SKUs to be grouped by channels rather than by entire lanes.

The shuttle follows orders sent by an operator through a WiFi connected tablet. It deposits its load in the first free location in the channel, while compacting the pallets as much as possible. Not having forklift traffic inside the lanes increases storage capacity in terms of depth and decreases the risk of accidents. Damage to the shuttle racks is then negligible, operator movements are optimized and warehouse operations modernized and made more flexible.

An ideal solution for companies handling high volumes of single-SKU pallets, as well as intense loading and unloading activities.

Multiple advanced functionalities easily controlled from a single tablet.

Advantages

Technology applied at top operating speeds.

Save space

Store more pallets deep, since channels can stand more than 131 ft high. The maximum verticality is determined by the handling equipment used.

The system works with minimal clearances between levels, which permits high-density storage.

Built-in sensors on the shuttles help position loads intelligently, eliminating empty spaces in the storage lanes. As a result, the effective capacity of the warehouse (which considers goods flowing in and out of the warehouse) reflects its physical capacity.

Save time

Loading and unloading times are reduced, since the operator does not have to move around inside the lanes.

The shuttle can travel at speeds of 295 ft/min when empty, or 148 ft/min when loaded.

Load lifting cycle of just 2 seconds.

With just a single command, the shuttle can progressively fill or empty a whole lane.

Increased productivity

More goods flowing in and out of the warehouse.

Unlike standard drive-in systems, items can be grouped by channels, rather than requiring a full lane. Greater product diversification is the result.

Optimization of operator movements through the product-to-person system, i.e., the load that moves to the operator.

While the Pallet Shuttle carries out a command, the operator collects another pallet, achieving continuous workflows.

Depending on temperature and load conditions, the shuttle can operate up to 10 hours, working at full performance.

The easy-access lithium batteries have fast connections, makeing them cable-free. So, battery units can be changed quickly without interrupting the operational cycle.

Elimination of errors.

The shuttle rack system is easy to use and maintain.

A single tablet can control up to 18 shuttles.

Inventory function means the shuttle counts how many pallets are stored in a channel.