Vapor recovery systems

Responds instantly to spikes in produced gas volume (separator dumps) to attain full capture.

Lower maintenance by preventing formation condensates in the compressor oil.

Uses throttle and bypass control rather than compressor speed to modulate throughput and control tank / VRT pressure to within 2 oz.

Self-adapting to local atmospheric pressure. (Altitude)

Cold Weather options using insulation and heat trace.

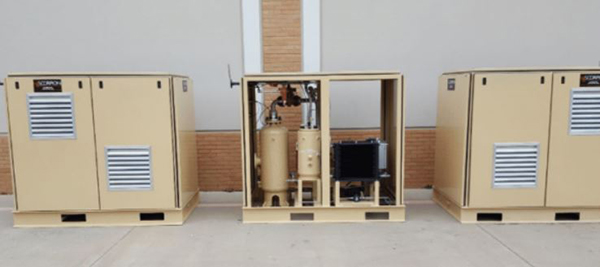

Fully enclosed skid packages for weather protection.

Operator friendly controls with safety interlocks, data logging, and SCADA capability.

Optional O2 sensing and divert to combustor option available.

CL1 div.2 or optional CL1div.1.

Robust, low maintenance flooded screw compressors.

Forced-Draft stabilizer optional.

Factory tested and shipped ready to run with minimal setup.

Custom sized and designed Specifically for your application.

Optimum response to fluctuations in produced gas volume

How is this achieved?

First, we must consider the popular method. Volume capacity in conventional VRUs is controlled by varying compressor speed by means of a VFD. VFDs inherently produce heat and tend to fail in oilfield environments because of heat buildup. Electric motors also tend to overheat when slowed below 50 Hz.

Once the motor and compressor have reached minimum speed. Any remaining turndown must be achieved by means of capacity bypass. This type of setup struggles to achieve 100% turndown especially if the compressor is oversized. During times when there is little to no flow this setup must stop the compressor and restart. This allows the compressor to cool between cycles and spend less time at optimum temperature which allows condensates to form in the compressor oil. Shortening compressor life and increasing maintenance costs.

What would provide better function?

The volume capacity is controlled by means of an automatic pressure sensing inlet and bypass valving arrangement between the inlet scrubber and the compressor intake. This arrangement allows the compressor to run at constant speed and provides instantaneous response from zero flow to full capacity.

This allows for full capture of produced gas with no risk of inducing air into the stream. The compressor is maintained at optimum operating temperature.to prevent formation of condensates in thecompressor oil. Extending service intervals and compressor life while decreasing cost of ownership.