CUSTOM ALUMINUM EXTRUSIONS

CUSTOM ALUMINUM EXTRUSIONS

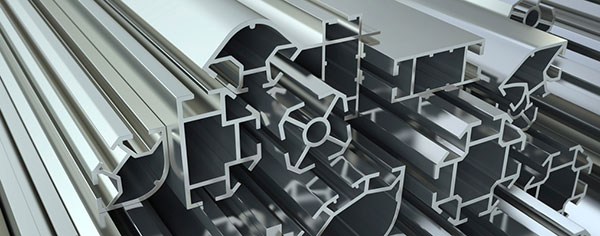

Bonnell Aluminum is a manufacturer of custom aluminum extrusions. Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the same profile as the die opening.

To aid in understanding the aluminum extrusion process, think about a Play-Doh® Fun Factory and how it works. Think of the Fun Factory as the extrusion press, the handle as the ram, the shape bar as the die, and the Play-Doh® as the aluminum billet. The first step is to choose the desired shape and color. Think of the shape as the die and the color as the temper and alloy needed. Next, the Play-Doh® is inserted into the holding chamber and pressure is applied to the handle, which forces the Play-Doh® through the shape. In an extrusion press, pressure is applied to the aluminum billet by the ram where the dummy block is attached to the end of the ram stem. When Play-Doh® begins to emerge, it has effectively been "extruded". The same principles apply to extrusions from aluminum billets but considerably more detailed and sophisticated technologies are involved.For more information, please visit our Extrusion Process page under Resources.

BENEFITS OF CUSTOM ALUMINUM EXTRUSIONS

- Highly suitable to receive a wide range of finishes - paint, anodizing

- Can easily be fabricated - cutting, drilling, punching, machining, bending, and other conventional fabrication methods

- Can be joined to other aluminum products or to different materials by welding, soldering, brazing, bolts, rivets, clips, adhesives, clinching, slide-on, snap-together, interlocking joints

- Can be designed for easy and reduced assembly

- Can be designed and produced as complex and integral shapes

- Can be designed and produced to close tolerances

- Aluminum extrusions can be recycled and re-melted back into aluminum

In addition to custom extrusions, we have a number of profiles available for mill order quantity production. Please see our Standard and Architectural Shapes catalogs for more details.

USES OF ALUMINUM EXTRUSIONS

Whether you need a simple shape, a complex hollow, or highly custom aluminum extrusion profiles, Bonnell Aluminum can extrude it. With our state-of-the art technology, combined with our customized approach, we can handle your toughest aluminum extrusion challenges. We deliver on-time results that will keep your business running smoothly.

QUALITY ALUMINUM EXTRUSIONS AT AFFORDABLE PRICES

With every aluminum extrusion task we undertake, we focus on lean manufacturing techniques. We cut our raw billets to the optimal extrusion size to minimize scrap and waste and we prepare our dies in state-of-the-art die ovens to speed up die changeover times. It’s all part of our ongoing commitment to manufacturing efficiency and customer satisfaction.

ACCURATE ALUMINUM EXTRUSION PROFILES

Whether you need standard aluminum extrusion profiles or custom ones, look no further than Bonnell Aluminum. Our new Ascona Vision System technology uses one of the largest telocentric camera lenses ever produced. Made by Carl Zeiss, this machine allows us to measure extrusion dimensions more accurately and far more quickly. We can measure dimensions that would have been impossible to measure with calipers. These lenses have lowered our manufacturing costs and we look forward to passing the savings onto our customers.

We also have the ability to get more accurate weight per foot using the latest extrusion technology. By easily creating measurements and manufacturing reports for our customers and die vendors, this technology guarantees that we distribute only the most accurate custom aluminum profiles.