Cold Rollforming

Cold Rollforming

Cold rollforming is one of the most versatile and productive manufacturing methods ever devised for forming metal.

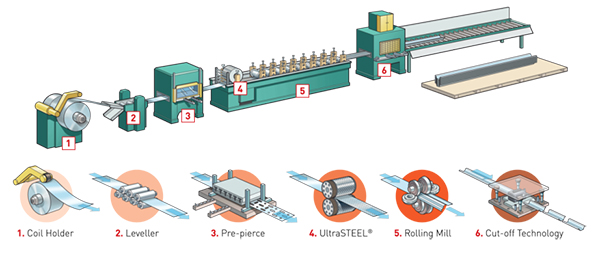

The process takes the form of a continuous bending operation in which a long strip of coiled metal (usually steel) passes through a series of contoured rolls, progressively forming the metal to achieve the desired cross-section profile.

This advanced manufacturing process is:

- Ideal for constant-profile parts with long lengths and in large quantities

- Maintains a high degree of consistency and accuracy

- Suitable for a wide range of metals

- Allows for custom product design and manufacture

- Effective solutions to complex challenges

Our market leading roll forming technology means that or profiles offer a number of advantages over extrusions, including significant savings in weight and increased strength (having been work hardened in a cold state). In addition, the rollforming process is more rapid and takes less energy than extrusion.

One of our key strengths is the ability to translate complex custom requirements into high quality, effective solutions and our pioneering use of advanced software and technology enables more efficient product development and allows for a quicker turnaround for cold roll forming.

Our custom rollforming service combines our engineering capabilities and technological expertise, opening the door to new possibilities in terms of cross-section profiles. Our experts will work with you every step of the way to develop the most appropriate, efficient production solutions for your application, reducing design and manufacturing time whilst simultaneously ensuring outstanding quality and accuracy. We can offer:

- Materials up to 8mm thick, up to 1.3m wide

- Wide range of geometric possibilities

- Tolerances as low as ±0.05mm

- SPC and Process Capability Analysis

- Suitable for ferrous, nonferrous, stainless steel and other malleable metals

- Ability to form materials with polished surfaces and pre-coated materials

- In-line features including hole punching, notching, embossing and cut to length

- In-line welding enables enclosed shapes

UltraSTEEL® is a major technical breakthrough in the development of rollforming, and can be applied to virtually any cold rolled profile. Visit our UltraSTEEL® page for more information on this internationally patented process.