ANSON 2500 SERIES BEARINGS

ANSON 2500 SERIES BEARINGS

Versatile 2500 Series Bearings

Having bearing problems? Anson Sales of Delta, British Columbia thinks it has the answer to some of those problems.

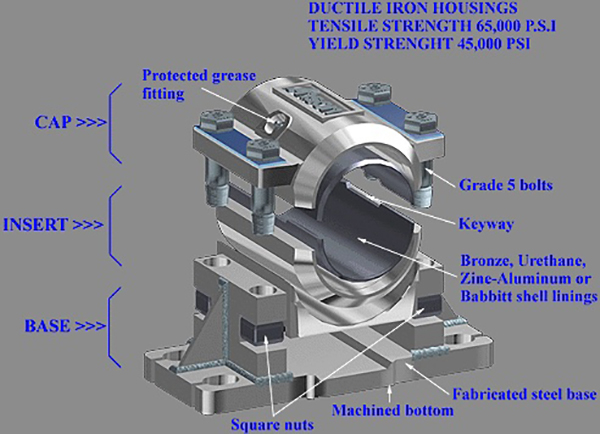

Anson’s 2500 Series unit has a horizontal split with a gib. It is a three-part bearing and can be supplied with babbit, polyurethane, bronze or zinc aluminum lining. The zinc aluminum lining is being used as an alternative to SAE 660 bronze, giving a similar service life as bronze at a much reduced cost, according to Anson. The zinc aluminum is poured “in house,” thus ensuring fast service.

The most popular lining used in the Anson bearing is the polyurethane, which has an excellent “memory” and readily absorbs impact and shock loading, says Anson. The unit utilizes a split ductile iron housing and fabricated steel base.

Anson’s revolutionary roll-out shell design offers the user the quickest and simplest bearing replacement in the market today. The four bolts on the cap portion are removed and the cap pops off; remove two keys and the old roll-out shell; roll the new shell in and replace the keys and cap. The entire replacement is accomplished without disturbing the shaft assembly and alignment.

They’ll also interchange with regular bearings of the same dimensions and can be welded down where there is lots of vibration.

Other Anson products are the 1000 Series, one-piece bearing block, and the ATU Series all steel fabricated conveyor or take-up frames, 40 degree angle split bearing and flange bearing with roll out shell.

Features & Applications

These bearings are designed to facilitate the removal and replacement of the bearing element without disturbing the shaft alignment.

After removing the cap the bearing element can be replaced, and the cap bolted down.

The bearing elements are available in Babbitt, Urethane, Zinc Aluminum and Bronze Bushed, and are interchangeable. Grade 5 bolts are used, and are prevented from turning loose by the use of keeper plates under the bolt head. Square nuts are located in recesses and are locked in place. Grease fittings are at 45 degrees and are countersunk into cap to prevent damage.