Electrical Enclosures

Electrical Enclosures

Key Design Considerations for Electrical Enclosures

When manufacturing custom electrical enclosures, there are several factors to keep in mind to ensure the finished products accommodate the requirements and restrictions of their intended use cases. Some of the key considerations are:

NEMA ratings allow users to easily determine whether an enclosure is suited to their application. For use in non–hazardous indoor locations, enclosures with NEMA ratings of 1, 2, 4, 4X, 5, 6, 6P, 12, 12K, and 13 are appropriate. For non-hazardous outdoor locations, enclosures with NEMA ratings of 3, 3X, 3R, 3RX, 3S, 3SX, 4, 4X, 6, and 6P are a suitable option. For use in hazardous locations, the NEMA ratings required—including Class A to G and 10—vary based on the compounds present.

Durability. The conditions an enclosure may be exposed to influence how durable they should be. For example, if impact or tampering is expected, the material chosen should demonstrate the proper strength and sturdiness to minimize damage to the equipment.

Optional modifications. For OEMs or end–users with highly specific needs, it may be appropriate to make modifications to a standard enclosure to suit the exact specifications demanded. Alternatively, they can turn to custom–made solutions.

Thermal management requirements. High heat can damage sensitive electrical and electronic components. Integrating a cooling component can prevent thermal damage from occurring

Size. The size of the enclosure needed depends on the application and determines the ideal construction material. In regard to the latter, materials such as polycarbonate are generally used for small enclosures, while materials like steel and stainless steel are utilized in large enclosures.

Aesthetics. Some enclosures remain out of sight, while others are quite visible. For the latter, industry professionals may add elements that improve the aesthetic design of the piece, such as paint and other finishing touches.

Weight. Enclosures intended for wall mounting require lightweight construction materials. For these applications, materials such as polycarbonate and fiberglass have a much lower weight than a comparable amount of aluminum or steel.

Budget. While many enclosure options may suit an application, it is important to choose the one that fits within the budget. In regard to material, price varies based on the enclosure size, with some options being affordable in small enclosures but too expensive in large enclosures.

Material. Enclosures are available in many different materials, such as aluminum, copper, iron, and steel. As indicated above, the right material depends on many factors, including operating environment, size, weight, and budget.

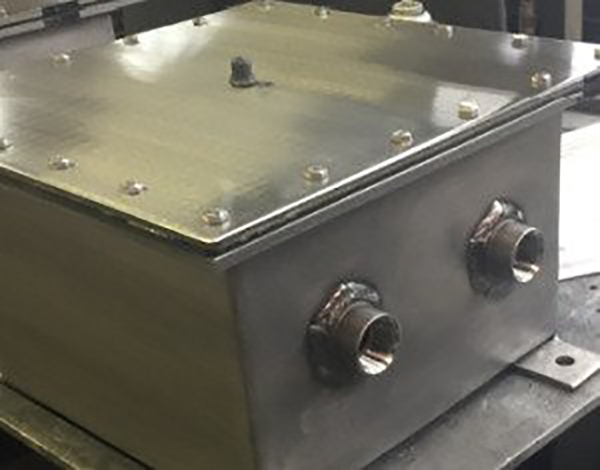

Fabricated Electrical Enclosure Products From Selco

At Selco, we provide a wide range of custom enclosures, cabinets, and housings for use in electrical applications. We accommodate requests for all NEMA ratings, including, but not limited to, NEMA 4X and NEMA 6P. We also fabricate FIRE RATED BOXES. Some of our other enclosure capabilities include:

Custom cable trays made from aluminum, stainless steel, or painted COR–TEN steel

Cabinets and enclosures for use in tunnels, bridges, substations, water, and wastewater treatment facilities and control and utility rooms.

Complete snow melters with fully integrated controls

General electrical components such as control panels and switch boxes.