RIGID SHAFT COUPLINGS

RIGID SHAFT COUPLINGS

Rigid shaft couplings “couple”—i.e., clamp onto and connect—two shafts aligned with each other. By joining the two shafts, these mechanical components enable the transfer of rotary motion from one rotating shaft (the driving shaft) to the other (the driven shaft).

At Stafford Manufacturing, we manufacture and distribute a broad selection of rigid shaft couplings for use in industrial and consumer products. Our coupling products find use in automation, motion control, power transmission, and other original equipment manufacturer (OEM) and maintenance, repair, and operation (MRO) applications.

OVERVIEW OF RIGID SHAFT COUPLINGS

The simple and durable design of rigid shaft couplings allows the components to transmit more power than comparable flexible shaft couplings but also prevents them from compensating for shaft misalignment. With these considerations in mind, industry professionals generally only use them for applications where the shafts are coaxial and/or pre-positioned in precise alignment with each other.

APPLICATIONS OF RIGID SHAFT COUPLINGS

Typical applications of rigid shaft couplings include:

- Shaft support and extension. If a driven shaft is not bearing supported, the driving shaft needs to provide support. For these situations, rigid shaft couplings are used to extend an unsupported shaft and to connect shafts of different diameters.

- High torsional stiffness requirements. In applications involving coaxial and/or pre-positioned shafts where the maintenance of high torsional stiffness along the rotational axis is important, a rigid shaft coupling gets the job done. These couplings have zero backlash and zero axial motion.

Industries which use rigid shaft couplings for these and other applications include food and beverage processing, medical, material handling, packaging equipment, and conveyor manufacturing.

TYPES OF RIGID SHAFT COUPLINGS

At Stafford Manufacturing, we manufacture and distribute four main types of rigid couplings:

- One-piece split clamp coupling. These couplings have higher torque capacities than set screw type couplings. They feature smooth straight-through or stepped bores that protect the shaft from damage and are available in three styles: heavy duty, high strength, and low profile.

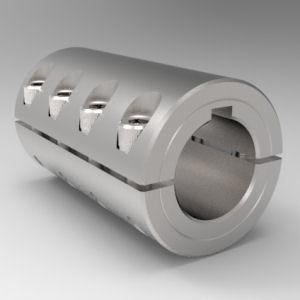

- Two-piece split clamp coupling. These couplings come in two pieces, allowing for easy assembly and adjustment. They can feature keyways that offer greater torque capacities and fixed shaft phasing.

- Three-piece split clamp coupling. These couplings are used to maintain the positioning of one shaft while the other shaft is adjusted. Similar to one-piece couplings, they feature smooth bores that minimize the damage experienced by the shaft.

- Precision sleeve coupling. These couplings provide a close tolerance fit on ground shafting. The axial runout is less than 0.001TIR. This precision machining mates two shafts with zero backlash and zero axial motion.