Tube Laser Cutting

LASER TUBE CUTTING - BLM LT5

The LT Fiber provides superior performance in thin wall materials.The faster cutting speed of nitrogen assist fiber laser cutting on thin materials more than doubles machine productivity compared to CO2cutting: thinner wall mild steel, stainless steel and galvanized are the materials that benefit the most from fiber laser cutting. Copper and brass, materials that cannot be cut with CO2 technology CO2 can be easily cut with fiber laser.

We are proud to offer tube laser cutting services to supply the varied needs of our customers. Our LT Filber tube laser can process pipes up to 4.75 inches in diameter with an exceptionally efficient flow of materials, resulting in greater production and less downtime. Entire cutting jobs are possible in one step with tube laser cutting. Our machine can process tube by simultaneously adding holes and completing complex cut-outs. All types of tube shapes can be handled including round, rectangular and square tubing. Tight tolerance and complex fabrications are also easily managed with our laser tube cutting machine.

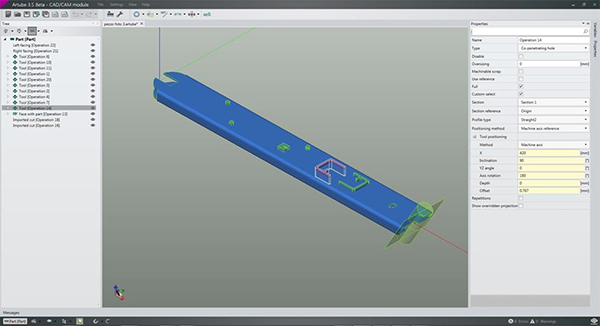

ARTUBE: 3D CAD/CAM for designing and programming tubular parts

Artube give us the ability to import 3D models created using external CAD systems with a single click.

We can process all formats: STEP, IGES, XT and even IFC

reate a drawing from scratch.

Electrochemical Machining (ECM)

Electrochemical machining (ECM) is a method of removing metal by an electrochemical process. It is normally used for working extremely hard materials or materials that are difficult to machine using conventional methods like stainless steel.

Burr-free smooth finish

Tight tolerance lengths

Ideal for tubing

Best suited for high-volume jobs

The process is used in aerospace engineering and the automotive, construction, medical equipment and power supply industries.

By using the ECM cutting process, we can create tube ends that boast the type of consistent quality required by industries with complex applications. For industries where the end cut is vital to tube performance, consistency is critical in determining how the tube will interact with varying assemblies. This process provides high-quality end formation that you can count on with no distortion or thermal stress. There are no changes in the material properties of the tubing and mechanical properties, such as hardness and toughness, stay intact.

Thanks to our dedicated on-site staff, we can deliver consistent tube cutting services time after time, adjusting the process to your unique requirements, tube sizes, and alloys.