Heating Without Gas - Shifting to Electric Heating Systems for More Eco-Friendly Production

The green revolution is accelerating in many industries, as next-generation electric heating systems gradually replace gas burners. But how can a furnace help achieve a business’s sustainability goals? Here, Daniel Burton, business manager at Kanthal, a provider of industrial heating products and services and part of Sandvik Group, explains how helping customers switch from gas to electric furnaces has achieved results that are worth celebrating.

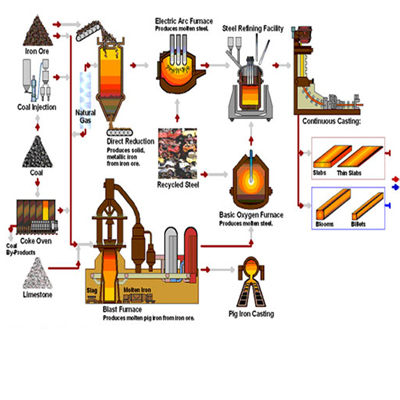

The integrated steel plants of today use many different thermal processes for steel production. For primary and secondary production, processes require heat to galvanize, anneal and heat treat steel products in general. Extreme heat requires extreme power and, because of this, furnaces play a vital role in fuelling steel production.

Cut the cost

However, all of this heat comes at a price. Most commonly, the furnaces that deliver the temperatures needed for steel production are powered by fossil fuels. While fossil fuels are effective, their negative impact on the environment is no secret. Yet demand for steel is rising. To support this potential, and also to further it, steel production must undergo some environmental improvements. One is to switch from fossil fuels to electric-powered furnaces.

Electric heating systems by Kanthal are designed for a range of industrial heating applications, including steel processing. They are shown to deliver significant reductions in energy consumption compared with gas-heated systems. In fact, the net efficiency of Kanthal electric heating systems is 70 per cent, compared with only 20 per cent for gas.

Electric furnaces can also help achieve a cleaner, safer and quieter working environment, making it a much healthier place for employees.

Go green

While electric furnaces demonstrate “a new dawn” of sorts for steel, the material’s long and unchanged history makes it difficult to realise new innovations.

To help its customers begin the process of switching from fossil fuels to electric-powered furnaces, and to help them reach their own sustainability targets, Kanthal has developed a service portfolio that includes a customised, onsite evaluation service. The service provides calculation models, reports and recommendations to help identify the best electric furnace for each customer’s specific needs.

The services are helping to deliver a measurable and lasting environmental impact for Sandvik, its customers and the planet. This is backed-up by data from measuring 34 installations of Kanthal electric furnaces across the globe. Kanthal tracks a running total of the CO2 savings that these furnaces have achieved. The total, which updates every second, has counted hundreds of millions of kilograms, so far.

Winning results

To recognise the success of Kanthal’s sustainable innovation, Kanthal Services was nominated for the first Sandvik Sustainability Award in Memory of Sigrid Göransson, named in honour of the famous Swedish philanthropist (1872-1963) who was born, and died, in Sandviken, Sweden, the town where the Sandvik Company was founded.

Award entries came from all three of Sandvik Group’s business units — Sandvik Materials Technology, Sandvik Rock and Mining Technology, and Sandvik Machining Solutions — all of which have made considerable progress towards the group’s sustainability goals. These objectives include halving Sandvik Group’s CO2 impact by 2030, towards which Kanthal Services significant contribution saw it crowned as the winner of this year’s award.

In addition to aiding Sandvik’s goals, Kanthal’s evaluation has helped its customers meet their own sustainability and workplace targets, comply with regional emissions rules, and have even facilitated support from the Government of Sweden for expansion projects.

Creative collaboration and identifying the need for change is a key to breaking age-old traditions, which include those relating to sustainability and steel production. While it’s clear that we need to change our approaches to industrial heating, executing these changes isn’t always easy.

That’s why, by implementing a progressive evaluation process, Kanthal and Sandvik have demonstrated that a simple switch can deliver significant progress. Using electric heating for processes such as anode preheating, the right equipment can contribute towards reducing CO2 emissions, even in unlikely applications.