Steel's Vital Role in Powering the Future: A Deep Dive into its Contribution to Renewable Energy Infrastructure

Introduction:

In the quest for sustainable and clean energy solutions, the global focus has shifted towards renewable energy sources, with wind and solar power leading the charge. Behind the scenes, the steel industry plays a pivotal role in supporting the development and success of these renewable energy projects. This article delves into the crucial role that steel plays in the construction and functionality of wind turbines, solar farms, and energy storage systems, highlighting how this robust material is a cornerstone of the renewable energy revolution.

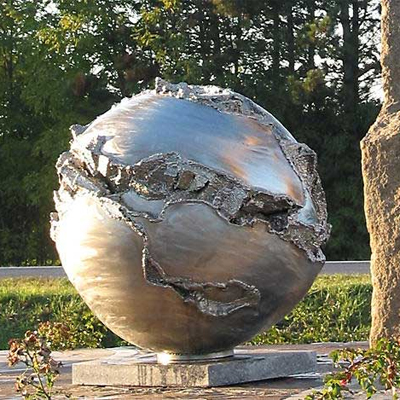

I) Wind Turbines: Harnessing the Power of Steel

1. Tower Construction:

The critical role of high-strength steel in the construction of wind turbine towers:

Wind turbine towers stand tall as the iconic symbols of renewable energy progress, and at their core lies the indispensable role of high-strength steel. The construction of these towering structures demands materials that can withstand the immense forces exerted by both the turbine's rotating blades and environmental conditions. High-strength steel alloys, renowned for their robustness and load-bearing capabilities, emerge as the optimal choice for such a critical application.

Advancements in steel manufacturing techniques:

In recent years, advancements in steel manufacturing techniques have propelled the durability and longevity of wind turbine towers to new heights. Cutting-edge methods, such as advanced welding technologies and precision fabrication processes, ensure that the steel used in tower construction exhibits superior structural integrity. These advancements not only enhance the overall performance of wind turbines but also contribute to reducing maintenance requirements and extending the operational lifespan of these structures.

Engineering challenges and how steel addresses them?

The engineering challenges inherent in designing and constructing wind turbine towers are multifaceted. These challenges include the need to withstand dynamic loads, turbulent wind forces, and potential fatigue over time. High-strength steel, with its exceptional tensile strength and resilience, becomes the linchpin in addressing these challenges. Engineers leverage the material's properties to optimize tower design, accounting for factors like tower height, weight, and wind load distribution. Through careful engineering and the right choice of steel alloys, the challenges posed by extreme operating conditions are effectively mitigated.

In essence, the critical role of high-strength steel in wind turbine tower construction is a testament to the material's adaptability and strength. As the demand for renewable energy grows, the steel industry continues to innovate, pushing the boundaries of what is possible in tower design and construction. The symbiotic relationship between steel and wind energy is integral to the success of renewable power generation, paving the way for a sustainable future powered by the strength and resilience of steel.

2. Blades and Nacelles:

Materials and manufacturing processes involved in crafting wind turbine blades, emphasizing the role of lightweight yet strong steel alloys:

The design and composition of wind turbine blades are critical factors influencing the overall efficiency and performance of a wind energy system. Here, the utilization of lightweight yet robust steel alloys plays a pivotal role. The materials employed in crafting these blades must strike a delicate balance between weight, strength, and aerodynamic properties. Advanced steel alloys, engineered to be both lightweight and durable, are integral to achieving this delicate equilibrium. Through a combination of precision manufacturing techniques and metallurgical advancements, the steel industry contributes to the creation of turbine blades that efficiently harness wind energy while maintaining structural integrity over their operational lifespan.

The use of steel in the fabrication of nacelles, the component housing critical machinery like generators and gearboxes:

The nacelle serves as the hub of a wind turbine, housing vital components such as generators and gearboxes. In this crucial component, the role of steel is indispensable. Steel's durability and resistance to harsh environmental conditions make it an ideal material for safeguarding the intricate machinery within the nacelle. The weight-bearing capacity of the steel ensures the structural stability of the nacelle, supporting the efficient functioning of the internal machinery even in the face of turbulent wind forces. By withstanding the rigors of constant movement and exposure to the elements, steel contributes to the reliability and longevity of wind turbine nacelles.

Innovations in steel design that improve turbine efficiency and performance:

In the ever-evolving landscape of wind energy, innovations in steel design continue to enhance turbine efficiency and overall performance. Engineers and metallurgists collaborate to develop steel alloys with improved fatigue resistance, corrosion protection and enhanced mechanical properties. These innovations not only contribute to the durability of turbine components but also enable the construction of larger and more efficient turbines. Advancements in coatings and surface treatments further augment steel's performance, reducing maintenance requirements and optimizing the aerodynamic characteristics of turbine components. The ongoing commitment to innovation in steel design reinforces its position as a driving force behind the evolution of wind turbine technology, ensuring that these structures are not only powerful but also sustainable in the long run.

II) Solar Farms: Steel's Support in Harnessing Sunlight

1. Structural Framework:

Significance of steel in the construction of solar panel support structures and framing systems:

The structural framework supporting photovoltaic panels is a cornerstone element determining the overall efficiency and durability of the installation. Steel emerges as a key player in this arena due to its unparalleled combination of strength, versatility, and durability. The significance of steel lies not only in its inherent robustness but also in its adaptability to various designs and configurations. The construction of reliable and resilient solar panel support structures heavily relies on the engineering properties of steel, ensuring that the framework can withstand environmental stresses and support the solar panels optimally.

The balance between structural strength and weight considerations, showcasing steel's advantages:

In the pursuit of designing efficient solar farms, the delicate equilibrium between structural strength and weight considerations becomes paramount. The support structures must bear the load of solar panels while minimizing the overall weight to enhance ease of installation and reduce material requirements. Steel, with its exceptional strength-to-weight ratio, proves to be a game-changer in achieving this balance. The material's ability to provide high structural strength without unnecessary bulk allows for the creation of streamlined and cost-effective support systems. Engineers leverage the advantages of steel to design structures that maximize the surface area for solar panels while minimizing the environmental footprint of the overall installation. The adaptability of steel in striking this crucial balance positions it as an indispensable component in the construction of solar farms, ensuring that the structural framework not only endures but also optimizes the harnessing of sunlight for clean and sustainable energy production.

2. Solar Panel Manufacturing:

The role of steel in the production of solar panels, particularly in the framing and support structures that ensure longevity and durability:

The production of solar panels involves a meticulous combination of materials and engineering to create efficient and durable photovoltaic systems. Within this intricate process, steel plays a pivotal role in ensuring the longevity and structural integrity of solar panels. The framing and support structures that encapsulate the delicate solar cells rely on steel's strength and durability to withstand the rigors of installation, environmental exposure, and ongoing maintenance. Steel's corrosion resistance and load-bearing capabilities make it an ideal choice for framing, protecting the sensitive components of solar panels, and contributing to the overall resilience of the solar energy system.

Recent advancements in steel technology that contribute to enhanced solar panel efficiency:

As the demand for more efficient and cost-effective solar panels continues to rise, the steel industry has responded with notable advancements in technology. Recent innovations in steel manufacturing contribute directly to enhanced solar panel efficiency. Engineers are developing steel alloys with improved thermal conductivity and reduced electrical resistance, minimizing energy losses within the solar panel structure. Coating technologies, such as advanced anti-reflective coatings and protective layers, further optimize the performance of steel-framed solar panels. These innovations not only contribute to increased energy yield but also extend the lifespan of solar panels, making them a more sustainable and economically viable energy solution. By staying at the forefront of steel technology, the solar industry harnesses the advantages of steel to propel the efficiency and durability of solar panels, marking a significant stride toward a more sustainable future.

III) Energy Storage Systems: Storing Tomorrow's Power with Steel

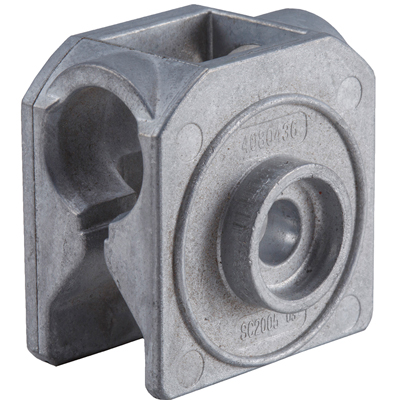

1. Battery Enclosures:

How steel is employed in the construction of battery enclosures for energy storage systems?

As the demand for efficient energy storage solutions escalates, the role of steel in the construction of battery enclosures takes center stage. The structural integrity and safety of energy storage systems heavily depend on the choice of materials, and steel emerges as a frontrunner. Steel's malleability and strength make it an ideal material for shaping the enclosures that house batteries in energy storage systems. The modular and customizable nature of steel allows for the creation of enclosures that can accommodate various battery configurations and sizes. Moreover, steel's adaptability facilitates the incorporation of safety features and ease of access for maintenance, contributing to the overall reliability of energy storage installations.

The importance of steel's strength and thermal properties in ensuring the safety and efficiency of these enclosures:

The construction of battery enclosures demands materials that can withstand both mechanical stresses and thermal challenges. Steel's exceptional strength and resilience become paramount in ensuring the safety and efficiency of energy storage enclosures. The robustness of steel protects against external impacts, environmental factors, and potential accidents, securing the batteries within. Additionally, the thermal properties of steel play a critical role in managing and dispersing heat generated during the charging and discharging cycles of the batteries. This is particularly crucial in maintaining optimal operating temperatures for battery systems, preventing overheating, and extending the lifespan of the stored energy. In essence, the combination of steel's strength and thermal conductivity positions it as a cornerstone material in the construction of battery enclosures, ensuring the safety, reliability, and longevity of energy storage systems that are essential for harnessing and storing the power of tomorrow.

2. Grid Integration:

The role of steel in supporting grid integration for renewable energy storage, including steel infrastructure for power substations and transmission lines:

The seamless integration of renewable energy into existing power grids relies heavily on the robustness and reliability of the supporting infrastructure, and steel plays a crucial role in this intricate process. Power substations, serving as the nerve centers for electricity distribution, require durable structures capable of withstanding environmental elements and electrical loads. Steel, with its exceptional strength and resistance to corrosion, emerges as the preferred material for constructing substations. Similarly, the transmission lines that carry electricity from renewable energy sources to end-users depend on steel towers and pylons for support. The high tensile strength of steel ensures the structural integrity of these transmission structures, facilitating the efficient and secure transmission of renewable energy across the grid.

Challenges of integrating renewable energy into existing grids and how steel solutions address these challenges?

The integration of renewable energy into existing power grids presents a unique set of challenges. The intermittent nature of renewable sources, such as solar and wind, requires a flexible and adaptive grid infrastructure. Here, steel solutions prove invaluable in addressing these challenges. The modular nature of steel components allows for the swift construction and modification of grid structures to accommodate fluctuations in energy production. Additionally, the use of advanced steel alloys enhances the resilience of grid components against the dynamic forces exerted by variable energy inputs. Steel's ability to withstand extreme weather conditions ensures the longevity of transmission infrastructure, reducing maintenance needs and enhancing the overall reliability of the integrated grid system. In overcoming the challenges of grid integration, steel emerges as a cornerstone material, providing the strength and adaptability needed to create a resilient and efficient grid capable of seamlessly incorporating renewable energy sources into the mainstream energy supply.

Conclusion:

In conclusion, steel emerges as an unsung hero in the realm of renewable energy infrastructure. Its versatility, strength, and durability make it an indispensable component in the construction of wind turbines, solar farms, and energy storage systems. As the world pivots towards sustainable energy solutions, the steel industry's innovations continue to drive progress, ensuring that the infrastructure supporting renewable energy remains reliable and resilient. The collaboration between the renewable energy and steel industries is a testament to the symbiotic relationship that propels us toward a greener and more sustainable future.