Zinc Nickel Plating Alternative

Pure aluminum is clearly better than Zinc Nickel Plating

Electroplated aluminum is a superior choice to low hydrogen embrittlement zinc nickel (LHE ZnNi) plating, offering more uniform composition, improved embrittlement mitigation, and unsurpassed corrosion performance and fluid compatibility.

Pure electroplated aluminum and LHE ZnNi are the leading commercial alternatives to cadmium for protection of aerospace components. Extensive DoD OEM testing indicates AlumiPlate® aluminum consistently outperforms LHE ZnNi and has become the premier anti-corrosion coating for high strength components in severe environments.

99.99% Pure Aluminum Has Unsurpassed Performance in Sulfur Dioxide (SO2)

Aluminum plating benefits from the synergistic effects of purity, a dense structure, high electronegativity, chemical resistance and a self-healing protective oxide layer. The result is unsurpassed barrier and sacrificial corrosion resistance imparted to nearly any base material.

Accelerated corrosion testing has been used historically to determine the relative corrosion resistance of coatings like ASTM B-117 salt fog testing. With the higher performance envelope of new aircraft, more stringent types of accelerated corrosion testing using sulfur dioxide (SO2) are the current barometer for coating performance in severe environments.

Electroplated aluminum leads the way in accelerated and environmental corrosion protection.

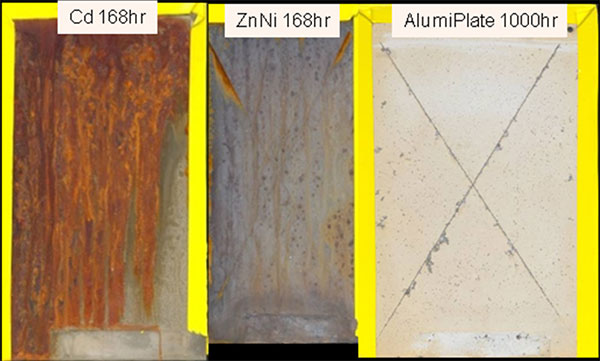

In side-by-side testing with ZnNi and a Cd control, aluminum plated 4130 steel coupons showed extremely high corrosion resistance. To test both barrier and galvanic (sacrificial) protective capabilities, the coatings were scribed prior to ASTM G-85 cyclic SO2 salt spray testing. Plating thickness was equivalent at 12.5 micrometers minimum.

Specimens with zinc nickel plating showed indications of red rust after 168 hours, while electroplated aluminum specimens lasted 668 hours before indications of base metal corrosion (refer to photos below in Figure 1). The impressive performance of scribed coupons with exposed steel is a testament to the extraordinary sacrificial protection capabilities of electroplated aluminum.

Electroplated aluminum helps achieve maximum protection and extends the life of components in a severe environment. With over 20 years of experience, AlumiPlate can engineer and help specify a custom solution based on your application needs.