PRIMARY BELT CLEANERS

Conveyor Belt Cleaning Solutions: MaxClean Primary Cleaners

A primary cleaner is usually positioned against the drive pulley right below the material flow. The primary cleaner removes most of the material that adheres to the belt after unloading – a vital task. Benetech’s MaxClean primary conveyor belt cleaning solutions get the job done in ensuring a safe, clean, productive operation.

Patented BEP1 – Best Seller

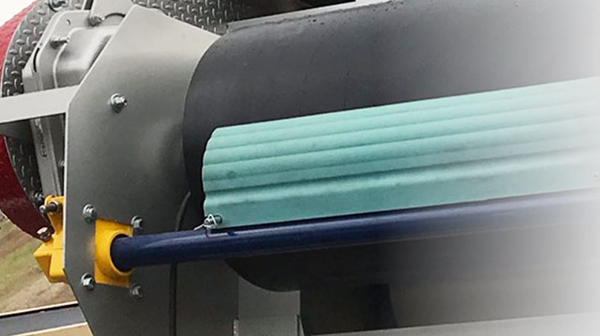

Featuring our patented AdvantEdge technology, Benetech’s BEP1 primary conveyor belt cleaning system includes an abrasion-resistant polyurethane blade that cleans the belt efficiently while extending its life. A revolution in primary cleaners, the BEP1 outlasts, out cleans, and outperforms other cleaners in the market.

Simple to install and maintain, the BEP1’s compact modular design mounts easily in tight chute applications. The conveyor belt scraper blade can be positioned on the head pulley in a range of locations. A unique wave profile allows for a varying attack angle that reduces blade-edge bull-nosing. The conveyor belt scraper blade also can be retrofitted to other cleaner brands.

Safe and quick blade changes are another advantage of Benetech’s primary conveyor belt cleaning solutions, which is especially true for the BEP1. For example, remove one blade pin, pull out the worn blade, slide in the new blade, and then replace the blade pin.

A self-contained torsion tensioner makes the BEP1 easy to re-tension as well. The tensioner’s self-adjustments also maintain consistent cleaning as the blade wears.

Optimized for vulcanized belts, the BEP1 conveyor belt scraper provides the cleaning power of a metal blade. It is ideal for material handling applications for coal-fired power plants, steel mills, aggregate, ports, cement plants, sawmills, pulp mills, and mining.