Double Disc Grinding Services

Double Disc Grinding Services

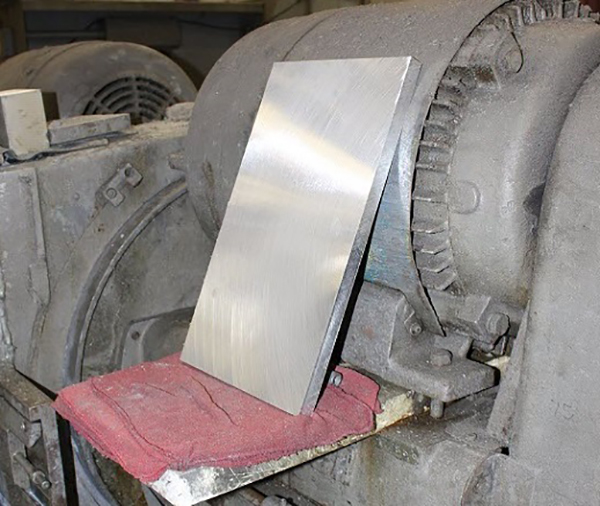

Double-disc grinding is an extremely efficient grinding process that uses abrasive wheels that oppose one another, grinding and removing equal amounts of stock from both sides of a blank. The result is a flat aluminum or stainless steel machine-ready blank with parallel tolerances to .0005” and finishes to 16 Ra. At DIX Metals, our double-disc grinding services can substantially reduce your pre-machining costs.

Double-disc grinding’s primary advantage is that metal blanks can be machined at twice the rate of conventional methods. Additionally, closer tolerances can be guaranteed that are attainable with either vertical or horizontal milling processes. Thinner and larger metal blanks are more likely to flex, thus the greater need for double-disc grinding.

There are also other benefits that double-disc grinding services provides, including a reduction of internal stress in many metals. With reduced stress, the stability of a machine-ready blank is improved for additional machining phases. Double-disc grinding is also very cost-effective for high-volume production, because of the savings in labor and machine hours.

Materials for Double-Disc Grinding

Dix Metals can perform double-disc grinding on any of the following materials:

- Aluminum

- Bronze

- Steel

- Raw metal

- Ferrous or non-ferrous metals

- Stainless steel

- Tool steels

- Cast iron

- Mold plate

- Copper

- Virtually any material

Dix Metals provides double-disc grinding services to manufacturers and machine shops requiring the highest quality product available. Our eight double-disc grinders can quickly remove material on opposing planes.

Advantages of Double-Disc Grinding

- Flatness and parallel tolerances to .0005”

- Smaller parts can actually be guaranteed within tenths