CUSTOM SHEET METAL FABRICATION SERVICES

CUSTOM SHEET METAL FABRICATION SERVICES

Custom Sheet Metal Fabrication Request Quote

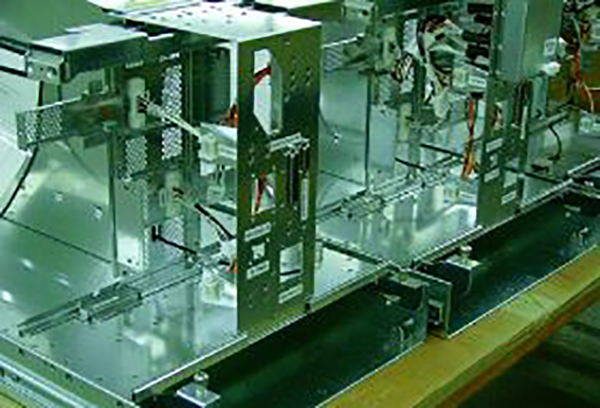

H&S Manufacturing offers high quality custom sheet metal fabrication services for clients in a broad range of industries, from lighting to medical and defense. Our AS9100D and ISO 9001:2008 registered facility specializes in prototype to full production volume, utilizing shearing, punching, graining, notching and extruding processes. This facility is equipped with modern high-speed multi tool equipment such as punch-laser machines, laser cutting machines, and punch presses. These capabilities allow us to produce parts from materials such as aluminum, cold and hot rolled steel, stainless steel, brass, and copper.

With over 40 years of experience we know how to maintain tight tolerances; for example, we hold a bend tolerance of ±.005″ hole to hole tolerance of ±.005″, hole to edge of ±.010″, and hole to bend of ±.015″ in material thicknesses of .015″ to .187″. Available finishing options include plating, silk screening and painting. We practice value engineering and efficiency methods and are dedicated to lean manufacturing. Specializing in customer service, we cater to client needs from consultation to finished product.

For more information on our custom sheet metal fabrication services, please see the table below or contact us directly.

PAST PROJECTS

Precision Form in Place Gasket Aluminum Exhaust Side Shield

Precision CNC Milling of Aluminum Monolithic Heatsink

Fabrication of a Stainless Steel Tank Drawer

Fabrication of a Steel Cart Frame

Assembly of a Stainless Steel Chassis Probe

SHEET METAL MANUFACTURING CAPABILITIES

Fabrication Processes

Shearing

Punching

Laser Cutting

Notching

Forming/Bending

Extruding

Louvers

Lances

Graining

Grinding

Deburring

Sand Blasting

Secondary Processes

Heat Treating

Welding

Spot welding

Wet Painting

Powder coating

Plating

Silk Screening

Hardware Installation

Mechanical Assembly

Precision Liquid Dispensing (FIP)

Equipment

Punch-Laser Machine

Laser Cutting Machine

Punch Press

Timesavers

Haeger Hardware Insertion

Press Size

Up to 33 tons

Raw Material Forms

Coil

Sheet

Materials

Aluminum

Cold Rolled Steel

Hot Rolled Steel

Stainless Steel

Brass

Copper

Galvanized

Finishes

Graining

Plating

Powder Coating

Wet Paint

Silk Screening

Plating

Conversion Coating (Alodine)

Zinc

Nickel

Anodize

Tin

Gold

Silver

Passivation

Material Thickness

.015 to .187 in

Bend Tolerance

±.005 to ± .010

Tolerance for Distance

Over 2 Bends (2B) ± .020″

Hole to Hole (H2H) ± .005″

Hole to Hole Over 2 Bends (H2H/2B) ± .020″

Hole to Bend (H2B) ± .015″

Hole to Edge (H2E) ± .010″

Edge to Edge (E2E) ± .020″ (Constrained)

Hole to Hole Over 4 Bends (H2H/4B) ± .020″ (Constrained)

Edge to Bend (E2B) ± .015″

Value Engineering

Manufacturability

Cost Reduction

Production Volume

Prototype to Production

Production Lead Times

4 weeks

ADDITIONAL INFORMATION

Industry Focus

Military and Defense

Medical

Lighting

Electronics

Energy

Communications

Transportation

Intended Applications

Computer Chassis

Testing Equipment

Rack Solutions

Industry Standards

AS9100D Certified

ANSI

ASTM

ITAR Compliance

ISO 9001:20015 Certified

Mil-Spec

RoHS

Reach

AWS

Efficiency

Kanban

Lean Manufacturing

Just In Time (JIT)

ESMI

ERP

File Formats

SolidWorks

AutoCad

DraftSight

.STEP/.STP

.IGES

.DFX

.DWG