Tool Trials and Part Validation

Tool Trials and Part Validation

RPM has the infrastructure and plant to undertake tool trials and part validation in-house.

- Press and injection moulding tool trials in house

- Shorter delivery timeframes

- Accountability and process quality control

RPM’s 150 ton Arburg gives us the ability to trial injection mould tools and under-take part validation without the tool having to leave the premises. This greatly reduces the final delivery time to the client as well as providing the client with basic mould settings. The Arburg has a tie bar distance of 470mm x 470mm.

Currently tool trials too big for the Arburg are performed at a moulding company located 5 minutes away from RPM’s factory. We envisage having our own 500 ton moulding machine by December 2017 so that 90% of all injection tooling manufactured by RPM will be trialled in-house.

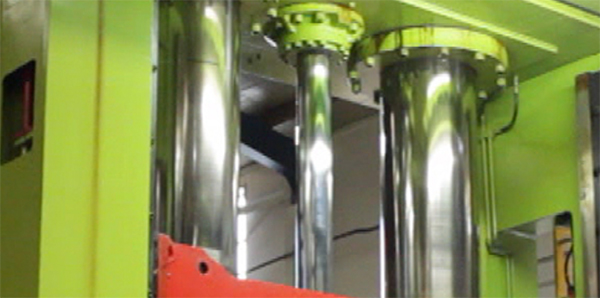

For all press tool trials RPM uses a 1000 ton hydraulic Chun Mu try out press with a bed size of 2788mm x 1721mm, and a maximum stroke of 1500mm. The smallest tool we can trial is 300mm high. This machine gives us the ability to trial all press tools manufactured by RPM. Once again, this in-house trialling speeds up the delivery process and part validation.

All part validations are accompanied with first article report and full measurement reports.

RPM exports tooling globally, so our ability to have complete control over the tool trial and part validation process is paramount. Our in house tooling trials and part validations provide strong assurance for customers that the tool and parts meet the agreed specification.