Streamlining Production and Improving Quality

Their current production process included too many steps and was increasing costs.

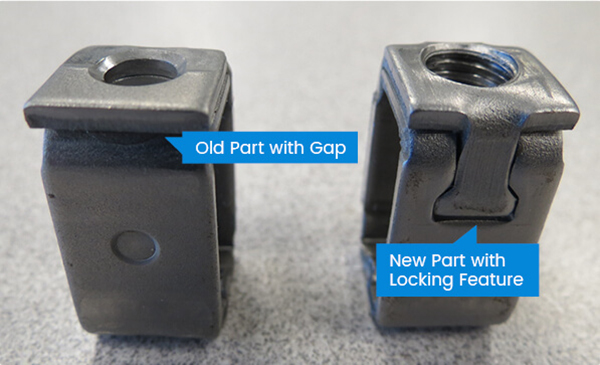

Misalignment on the top of the part was decreasing the quality and performance of

the inner threads.

Customer’s Goals

Reduce production time with an improved manufacturing method.

Eliminate the thread quality issue without significantly increasing costs.

Manufacturing Process

First, Ultra focused on fixing the alignment and thread quality issues which led to a minor redesign of box lug. We introduced a locking feature that minimized the gap and created a more secure fit. This can be seen on the box lug located on the right-hand side of the picture.

Second, Ultra addressed the increasing production times and that started with evaluating the tapping operation that was taking place after metal stamping. With the redesign of the box lug, it was the ideal time to add the tapping operation into the metal stamping process. Our team of Die Designers created a new progressive stamping die with two new operations.

Install the locking feature in one new station.

Install the tapping operation in another new station.

This resulted in the metal stamping of 1,680 box lugs per hour on the press. After this production is completed, Ultra manages the heat treating and plating services for this metal part as well. The production process is completed at our facility with final inspection and packaging for delivery.