Are Chains and Wire Ropes the Backbone of the Steel Industry?

Introduction

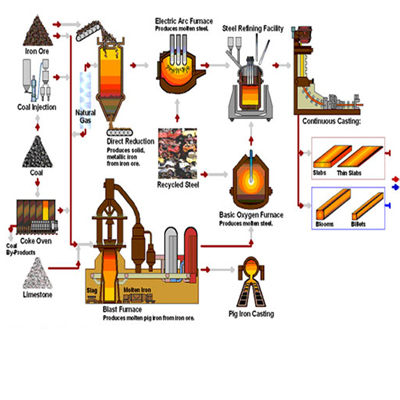

Chains and wire ropes are not just components but lifelines in the steel industry, intricately woven into the fabric of its operations. Their significance transcends mere functionality; they are the very backbone that supports and sustains the intricate machinery and processes of steel manufacturing. Chains, with their robustness and versatility, navigate the flow of raw materials like iron ore and coal within steel plants, ensuring a seamless journey from extraction to processing. On the other hand, wire ropes, with their high tensile strength and durability, elevate operations by facilitating vertical transportation in elevators and lifts, as well as providing crucial support in crane operations for lifting heavy loads during production. Together, these components enable the efficient movement of materials, foster safe handling practices, and contribute significantly to overall productivity and operational reliability within steel plants. Without the reliability and resilience of chains and wire ropes, the intricate dance of steel manufacturing would falter, highlighting their indispensable role in the industry's success.

Importance of Chains in the Steel Industry

Chains are indispensable in the steel industry, serving diverse roles throughout production and handling stages. They facilitate the movement of raw materials like iron ore and coal within steel plants, ensuring a continuous supply for processing. Heavy-duty chains are crucial in equipment such as cranes and hoists, supporting material handling and lifting tasks with reliability and strength. Their durability and ability to withstand harsh conditions contribute to operational safety and efficiency, minimizing downtime and maintenance costs. Chains' versatility extends to conveyor systems and equipment securing, making them integral components that underpin the smooth functioning of steel manufacturing processes globally.

Key Applications of Wire Ropes

Wire ropes are an essential component in the steel industry, valued for their high tensile strength and durability, which make them ideal for a range of applications. One key application is their extensive use in elevators and lifts within steel plants, where they facilitate the vertical transportation of materials and personnel with efficiency and reliability. Additionally, wire ropes play a vital role in crane operations, providing the necessary strength and stability for lifting heavy loads during steel production processes. Their ability to withstand heavy loads and harsh conditions makes wire ropes indispensable assets in ensuring smooth and safe operations within steel manufacturing facilities.

The Backbone of Steel Manufacturing

Chains and wire ropes are the backbone of steel manufacturing operations, working together to ensure the smooth functioning of various processes. They play a crucial role in facilitating the efficient movement of materials within steel plants, from raw material conveyance to finished product transportation. Additionally, they are essential for safe lifting and handling tasks, supporting the operation of equipment such as cranes and hoists. Their contribution to overall productivity and operational reliability is significant, as they enable steel plants to operate seamlessly and efficiently. Without chains and wire ropes, the challenges in material movement, lifting, and handling would pose significant hurdles to the smooth functioning of the steel industry.

Industrial Advancements and Innovations

Industrial advancements and innovations in chain and wire rope technology have revolutionized their performance and durability, particularly in demanding industrial environments such as the steel industry. One notable advancement is the development of specialized coatings and alloys that enhance the corrosion resistance of chains and wire ropes. These coatings and alloys not only protect the components from environmental factors like moisture and chemicals but also extend their service life significantly.

The improved corrosion resistance of chains and wire ropes reduces the frequency of maintenance and replacement, leading to cost savings and enhanced operational efficiency in steel plants.

Additionally, advancements in material science have resulted in chains and wire ropes with higher tensile strength and improved fatigue resistance, further enhancing their performance in demanding applications.

Furthermore, innovations in manufacturing processes have enabled the production of precision-engineered chains and wire ropes that meet stringent quality standards. This ensures consistent performance and reliability, crucial factors in the efficient operation of equipment and machinery in the steel industry.

Overall, industrial advancements and innovations in chain and wire rope technology have had a transformative impact on the steel industry, contributing to reduced downtime, improved safety, and increased productivity. These advancements continue to drive progress in the sector, pushing the boundaries of performance and durability in demanding industrial environments.

Conclusion

In conclusion, chains and wire ropes are indeed the backbone of the steel industry, playing indispensable roles in material handling, lifting operations, and overall operational reliability. The continuous evolution of technology and materials in chains and wire ropes contributes significantly to the efficiency and sustainability of steel manufacturing processes.

By understanding the importance and applications of chains and wire ropes in the steel industry, stakeholders can make informed decisions regarding equipment selection, maintenance practices, and safety protocols, ultimately contributing to the success and growth of the steel manufacturing sector.