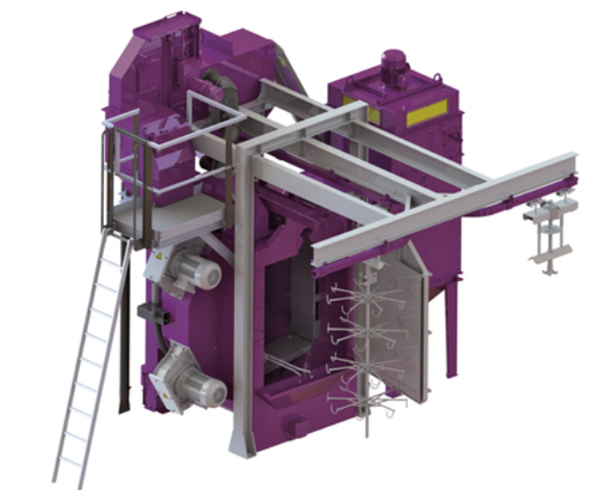

Monorail shot blast machine

Monorail shot blast machine

product range

Our standard program for monorail shot blasting systems includes several sizes.

The determination of the suitable machine concept depends, among other things, on the workpieces, the required performance and, last but not least, on the customer's ideas with regard to an optimal production process.

If the task cannot be solved with a standard machine, we will develop a tailor-made machine concept for you.

Please send your detailed inquiry to us.

Our experienced team will be happy to help you.

possible uses

Overhead conveyor blasting systems are among the most flexible types of blasting systems. They are used for a large number of workpieces for derusting, descaling, final sanding, deburring and finish blasting of sensitive components or for roughening surfaces for subsequent coating.

Basically, they are offered as a batch or continuous system. However, there are numerous intermediate forms that are based on the rail layout of the monorail system. In many cases, various processing processes such as blasting, painting and subsequent drying can be combined with the monorail system, which exploits an enormous potential for rationalization.

Further possible variations arise from the use of different blasting frames with the help of which the workpieces are fed into the machine. In many cases, standard blasting frames with plates, baskets or rods can solve the task. However, the requirements of our customers are always clarified in detail and often lead to a special solution.

operational process

The workpieces are hung on a blasting frame or directly on the rotating hooks of the chassis and pushed up to just in front of the steel system. An automatic feed device transports them to the first beam position.

After the program has started, the machine door is automatically closed and locked electro-pneumatically. The workpieces are blasted rotating in three positions according to the preset blasting time.

The abrasive is kept in circulation and cleaned for continuous use.

The cleaned blasting agent is transported from the blasting agent bunker to the high-performance turbines via the blasting agent dosing device.

After the end of the blasting cycle and after the turbines have come to a standstill, the machine door opens automatically and the workpiece hanger returns to the starting position.

A fan generates the required negative pressure for dust-free operation of the blasting systems. The extracted air is cleaned with a filter system.