SURFACE FINISHING

A wide range of custom stamped metals requires surface finishing as a part of the finishing process, from large automotive parts to miniature components for electronics, medical, consumer devices, and other applications. At Connor, we have extensive experience with metal finishing and understand the important aspects of cleanliness and surface finishing with respect to your product. Aside from aesthetics, there are many safety functionalities and industrial applications for it. It helps to prevent laceration from your workers and consumers, it improves the electrical conductivity, enhances resistance to corrosion, abrasions, wear and tear, and increases the solderability of metals among many other reasons.

There are a variety of metal finishing techniques like cleaning, polishing, passivation, anodizing, electroless plating, electroplating, powder coating, and liquid coating, etc.

Connor’s state-of-the-art automated ultrasonic DI water cleaning system has the capability to effectively clean parts from oil and contaminants. We are capable of achieving a 70 Dynes/cm surface tension, which provides better solderability for aluminum parts that require wire bonding application.

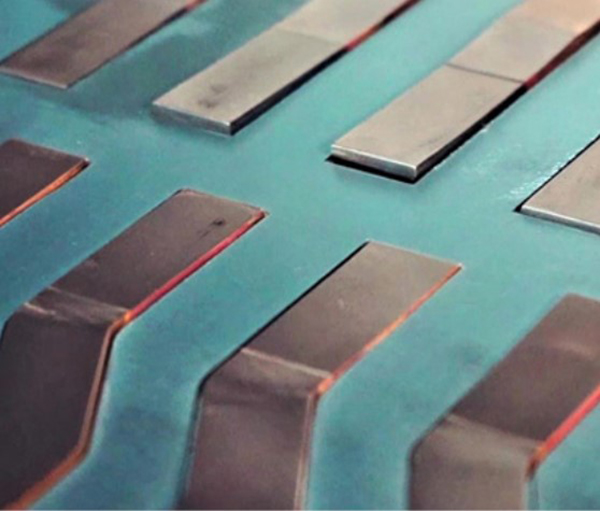

Connor is equipped with in-house deburring and polishing equipment, ranging from vibratory finishing, sand-blasting, and brushing. These various processes help remove sharp edges for greater safety, other material imperfections or surface flaws, cleaning and smoothing the surface, or creating uniform surface textures for appearance purposes.

For high aesthetic requirements, Connor is able to provide high uniformity anodizing finishing as well as hard coat anodizing.