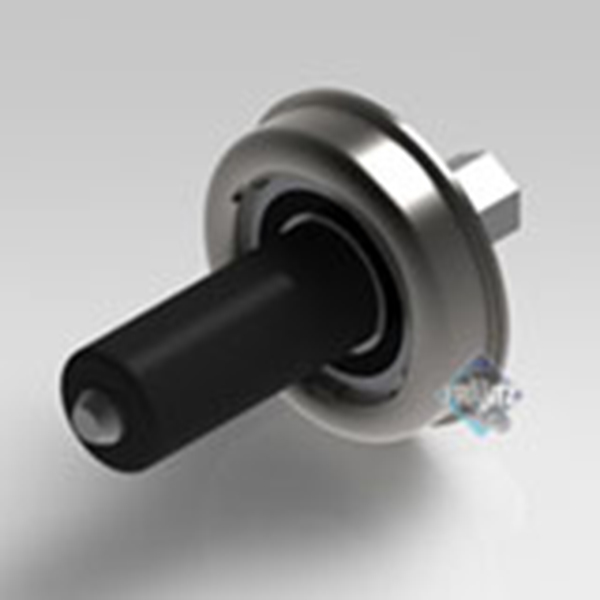

GenStar® Eliminator

GenStar® ELIMINATOR Bearings

FRANTZ® GenStar® Series of Precision bearings for conveyor rollers are simply better than our competition. Designed, engineered, and built in the USA, GenStar® Precision conveyor bearing assemblies are rigorously tested to assure that load ratings in this bearing category outperform our competition. FRANTZ quality promise means that we publish our bearing assembly load ratings and we stand behind our product. Click for information about Our Quality. Now, FRANTZ has taken our GenStar® line one step further to create our first axle-free bearing, the ELIMINATOR. It has features unlike others in the market. Compare….GenStar® ELIMINATOR bearings are simply better. This is the GenStar® ELIMINATOR value to you:

Reduced Axle Deflection

Enables the ELIMINATOR to perform at its load rating at longer lengths. With thru axles, minor deflection distorts and damages precision bearing races. Deflected axles can bump up against the inside of the roller tube at these lengths causing roller manufacturers to add “center pucks” adding cost and more weight. The elimination of a thru axle at longer lengths, allows for the tube to deflect without the same axle deflection on the ball races, permitting use of lighter gauged 1.9” rollers as a substitute for heavier and more costly 2.5” rollers in many pallet type conveyors.

IronGrip Adapters

Enable a far more secure mount than conveyor bearings housed with plastic adapters. Carbon steel adapters won’t walk out of your tube. FRANTZ has long championed its IronGrip Adapters by offering a broad line that cost effectively adapts smaller diameter bearings to larger diameter tubes. These adapter designs were incorporated into the FRANTZ popular GenII® line of semi precision bearings and its workhorse GenStar® line of ABEC-1 precision bearings. The carbon steel adapter allows for a very secure crimp fit roller assembly along with improved concentricity vs. plastic alternatives. The IronGrip adapter is designed to provide flexibility for various crimping pressures at the tube while isolating the ABEC-1 precision core bearing during the crimping process. FRANTZ engineers used this IronGrip Adapter design as the foundation for the new GenStar® ELIMINATOR which is unique among this style of conveyor bearing. The IronGrip Adapter allows for the use of a single ABEC-1 precision core bearing. The tube and mated bearing assembly carry the weight of products with reduced total roller deflection. Thus, it eliminates axle deflection as the determining factor in total roller load carrying capacity.

FRANTZ unique design

The ELIMINATOR begins with a single ABEC-1 core precision bearing providing a roller capacity of 270 lbs capable of spanning roller lengths through 40” with strong continued performance through 72”. FRANTZ engineers have tested the assembly performance to exacting CEMA standards with exceptional results. Inside the bore is a direct injection molded bushing made of nylon static discharge material. Both the steel adapter and the nylon direct injected bushing provide for excellent concentricity and extended bearing life. The dual sealed core ABEC-1 precision bearing is packed with Chevron SRI® grease providing a wide operating temperature range of -20° F to 350°F. The carbon steel stub shaft is spring loaded within the assembly with the spring being retained by an ultra sonic welded cap instead of commonly used clips. Roller installation is made easy by the shaft at each end being independently spring loaded.