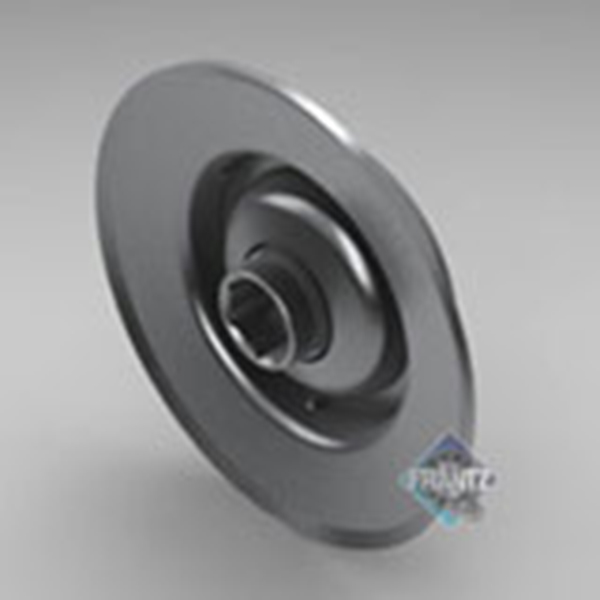

Stainless Steel Conveyor Bearings

Stainless Steel Conveyor Bearings

FRANTZ built its bearing reputation on the quality and performance of its Commercial grade Unground Non-Precision conveyor bearing assemblies for conveyor rollers.

Providing quality engineered conveyor bearing options for our customers is a FRANTZ value. Many of our Commercial grade Unground Non-Precision Conveyor Bearings are available in Stainless Steel which offers a greater range of protection from corrosion due to chemicals and the environment. These conveyor bearings are often used in outdoor, wash down, highly corrosive, and food processing environments. Because of the material chemistry, load ratings for Stainless Steel Commercial Unground conveyor bearings may be less than those published for similar carbon steel bearings. Please contact our Customer Service representatives for questions regarding load ratings.

FRANTZ utilizes two types of Stainless Steel in our Stainless Steel Commercial Unground Non-Precision Conveyor Bearing offerings:

300 Series Stainless Steel

This material is an austenitic non-magnetic steel which cannot be hardened by heat treatment. The steel hardens under pressure of use and provides reasonably good life under moderate loads. 300 Series Stainless Steel has a higher corrosion resistance than 400 Series Stainless Steel and can be used in high heat applications with temperatures up to 850°F with significantly reduced load rating. Load rating declines as temperature increases beyond normal ranges due to the effect of heat on the chemistry of the metal.

400 Series Stainless Steel

This material is a martensitic steel which is hardened by heat treatment. The stresses of the hardening transformation cause the material to exhibit permanent magnetic properties if magnetized in the hardened condition. Corrosion resistance is lower than 300 Series material but load carrying capability in the 400 Series is equal to related carbon steel bearing designs. These bearings can be used in applications with temperatures up to 450°F.

Lubrication

Regardless of the type of stainless material, the lubrication used should be compatible with the temperature. Dry lubricants such as Graphite or Molybdenum Disulfide should be considered in high temperature or high pressure applications as they do not smoke or vaporize away as with a petroleum based product. The degree of heat, the length of time a bearing is subjected to that heat, and the movement of air over the rollers (as in drying ovens) are factors that should be considered in selecting the type of lubrication for the bearing. Depending upon the application, customers may choose to run bearings dry but expected life will be reduced when running with no bearing lubrication. Click for Technical Information on standard conveyor bearing lubricants used in FRANTZ conveyor bearings. Contact our Customer Service representatives for consultative advice for lubricants in specialty applications.