Silvercorp To Acquire Adventus, Creating A Geographically Diversified Mining Company...

Silvercorp Metals Inc. and Adventus Mining Corporation are pleased to announce that the...

Kitco Metals Ranks 43 in the best places to work in Canada

Kitco Metals Inc. has established itself as a leading authority within the precious met...

Golden Arrow Commences Major Drill Campaign at the San Pietro Iron-Copper-Gold-Cobalt...

Golden Arrow Resources Corporation is pleased to report that it is now drilling t...

Power Nickel Releases Thick High-Grade Assays of Copper, PGMs, Gold and Silver from i...

Power Nickel Inc. is pleased to announce high-grade multi-elements assay results...

Metals Acquisition Limited Announces Updated Resource and Reserve Statement and Produ...

Metals Acquisition Limited ARBN 671 963 198 a private limited company incorporated unde...

U.S. Department of Energy announces financial support for ArcelorMittal's anticipated...

ArcelorMittal Calvert, wholly owned by ArcelorMittal, is planning for an advanced manuf...

Chemours Announces Dates for First Quarter 2024 Earnings Release and Webcast Conference...

The Chemours Company today announced that the Company expects to issue its first quarter 2...

C2C Metals Announces Chief Executive Officer

C2C Metals Corp., is pleased to announce, effective immediately, the appointment of Mr. Ja...

Power Nickel Extends Momentum - Closes Acquisition on 80% of Nisk

Power Nickel Inc. is pleased to announce it has completed the acquisition of an additional...

Nucor Invites You to Join Its First Quarter of 2024 Conference Call on the Web

In conjunction with Nucor's first quarter earnings release, you are invited to listen to i...

AISTech 2024

Mach-Tech 2024

2024 China (Guangzhou) Int’l Metal & Metallurgy Industry Exhibition

METALTECH & AUTOMEX 2024

Innovations in Strip Processing for Steel Industry Advancements

The steel industry is one of the cornerstones of modern manufacturing, providing essential materials for infrastructure, transportation, machinery, and countless other applications. Within this vast industry, strip processing plays a crucial role in transforming raw steel into usable, high-quality products. In recent years, significant innovations in strip processing technologies have driven

Towards Zero Waste: Innovations in Steel Recycling and Disposal

Steel is a vital material in various industries, from construction to manufacturing, due to its strength, durability, and versatility. However, the production and disposal of steel also contribute significantly to environmental challenges such as resource depletion and pollution. In recent years, there has been a growing focus on achieving zero waste goals, prompting innovations in steel recycling and disposal techniques.

How Do Minor Metals Enhance Steel Performance in Industry?

Steel is a fundamental material in various industries, known for its strength, durability, and versatility. However, the properties of steel can be significantly enhanced by the addition of minor metals. These minor metals, although present in relatively small quantities, play crucial roles in improving steel's performance, from enhancing its mechanical properties to increasing its

From Ore to Alloy: Navigating Ironmaking in Modern Steel Production

Steel is a foundational material in modern industry, essential for construction, manufacturing, transportation, and countless other applications. At the heart of steel production lies the intricate process of ironmaking, where iron ore is transformed into molten iron and eventually alloyed to create various grades of steel. This article delves into the journey from ore to alloy, exploring the technologies, challenges, and innovations that shape modern ironmaking.

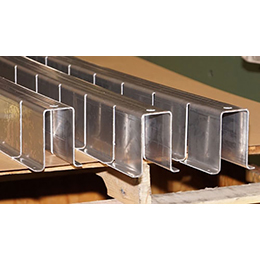

Crafting Excellence: Forming and Finishing Innovations in the Steel Industry

The steel industry is the backbone of modern infrastructure, providing the essential materials for construction, manufacturing, transportation, and numerous other sectors. At the core of this industry are the processes of forming and finishing, which play a crucial role in shaping raw steel into functional components with precise dimensions, enhanced properties, and aesthetic appeal. Evolution of Forming Techniques

Bhupinder Singh

Chief Executive Officer

Messe Muenchen India Pvt. Ltd.

Senior Research Fellow, Governance of Africa’s Resources Programme

South African Institute of International Affairs

Made in Steel s.r.l

MD, TSPDL

Tata Steel Processing and Distribution Ltd

Shyam Metalics and Energy Ltd, the leading and fastest growing metals manufacturing company in India, is proud to announce the establishment of a new...

Vista Metals announced their investment in a new location to serve the aerospace industry with specialty aluminum products. This new facility, located

INTOCAST AG announced the construction of a new, state-of-the-art production plant dedicated to the manufacture of MgO-C refractories and materials sp...

Flexco Products, a producer of tubing and steel and aluminum fabrication, plans to establish manufacturing and distribution operations in Lawrenceburg

.jpg)