SSAB and Nordec agree on deliveries of fossil-free steel

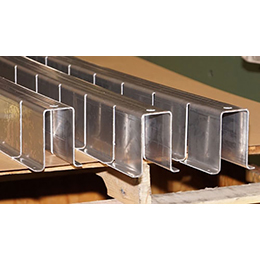

SSAB and Nordec have agreed on deliveries of fossil-free steel. Nordec will use the fos...

Luca Reports Successful Metallurgical Test Work For New Copper Concentrate At Campo M...

Luca Mining Corp. is pleased to report that the metallurgical test work on the copper-l...

U. S. Steel Battery-Powered Locomotives Receive “Governor’s Award for Environmental E...

United States Steel Corporation received the “Governor’s Award for En...

Vortex Metals Secures Conditional Approval for Illapel Copper Project

Vortex Metals Inc. is pleased to announce that it has received conditional approv...

Canada Nickel Company Concludes Successful Participation in Washington, D.C. Summit o...

Canada Nickel Company Inc. ("Canada Nickel") was proud to participate in an O...

Bechtel Establishes Joint Ownership of Unger Steel Fabrication FZE

Bechtel and Unger Steel have come together to form Unger Steel Fabrication FZE (Free Zo...

JR Machine Secures Strategic Investment from Schneider Resources Holding to Launch Expan...

JR Machine, a distinguished contract manufacturer specializing in complex machined parts,...

AZZ Inc. to Participate in the Oppenheimer 19th Annual Industrial Growth Conference and...

AZZ Inc. the leading independent provider of hot-dip galvanizing and coil coating solution...

OPTA GROUP LP ACQUIRES PERFORMIX METALLURGICAL ADDITIVES, LLC

Opta Group LP a portfolio company of Speyside Equity Advisers announces the acquisition of...

Sandstorm Gold Royalties Announces Sale of Select Non-Core, Non-Precious Metals Assets a...

Sandstorm Gold Ltd. is pleased to announce that the Company has signed a definitive asset...

AISTech 2024

Mach-Tech 2024

2024 China (Guangzhou) Int’l Metal & Metallurgy Industry Exhibition

METALTECH & AUTOMEX 2024

Optimizing Steel Quality: Insights into Secondary Metallurgy Techniques

Steel is a fundamental material in various industries, from construction to automotive manufacturing. The quality of steel directly impacts product performance and durability. Secondary metallurgy plays a crucial role in optimizing steel quality, enhancing its properties, and meeting stringent industry standards. This article explores key insights into secondary metallurgy techniques and their impact on steel quality.

Innovations in Strip Processing for Steel Industry Advancements

The steel industry is one of the cornerstones of modern manufacturing, providing essential materials for infrastructure, transportation, machinery, and countless other applications. Within this vast industry, strip processing plays a crucial role in transforming raw steel into usable, high-quality products. In recent years, significant innovations in strip processing technologies have driven

Towards Zero Waste: Innovations in Steel Recycling and Disposal

Steel is a vital material in various industries, from construction to manufacturing, due to its strength, durability, and versatility. However, the production and disposal of steel also contribute significantly to environmental challenges such as resource depletion and pollution. In recent years, there has been a growing focus on achieving zero waste goals, prompting innovations in steel recycling and disposal techniques.

How Do Minor Metals Enhance Steel Performance in Industry?

Steel is a fundamental material in various industries, known for its strength, durability, and versatility. However, the properties of steel can be significantly enhanced by the addition of minor metals. These minor metals, although present in relatively small quantities, play crucial roles in improving steel's performance, from enhancing its mechanical properties to increasing its

From Ore to Alloy: Navigating Ironmaking in Modern Steel Production

Steel is a foundational material in modern industry, essential for construction, manufacturing, transportation, and countless other applications. At the heart of steel production lies the intricate process of ironmaking, where iron ore is transformed into molten iron and eventually alloyed to create various grades of steel. This article delves into the journey from ore to alloy, exploring the technologies, challenges, and innovations that shape modern ironmaking.

Bhupinder Singh

Chief Executive Officer

Messe Muenchen India Pvt. Ltd.

Senior Research Fellow, Governance of Africa’s Resources Programme

South African Institute of International Affairs

Made in Steel s.r.l

MD, TSPDL

Tata Steel Processing and Distribution Ltd

Shyam Metalics and Energy Ltd, the leading and fastest growing metals manufacturing company in India, is proud to announce the establishment of a new...

Vista Metals announced their investment in a new location to serve the aerospace industry with specialty aluminum products. This new facility, located

INTOCAST AG announced the construction of a new, state-of-the-art production plant dedicated to the manufacture of MgO-C refractories and materials sp...

Flexco Products, a producer of tubing and steel and aluminum fabrication, plans to establish manufacturing and distribution operations in Lawrenceburg

.jpg)

.jpg)